Are you a tea or coffee producer experiencing frustrating bottlenecks and inconsistent quality in your drip coffee bag packaging, feeling overwhelmed by the complexity of achieving both a perfect inner filter bag and an appealing outer envelope automatically, risking compromised product freshness, inaccurate produce weight, and inefficient production capacity? The challenge of seamlessly combining these two delicate packaging stages into one automatic drip coffee bag packing machine can drain resources and delay market entry.

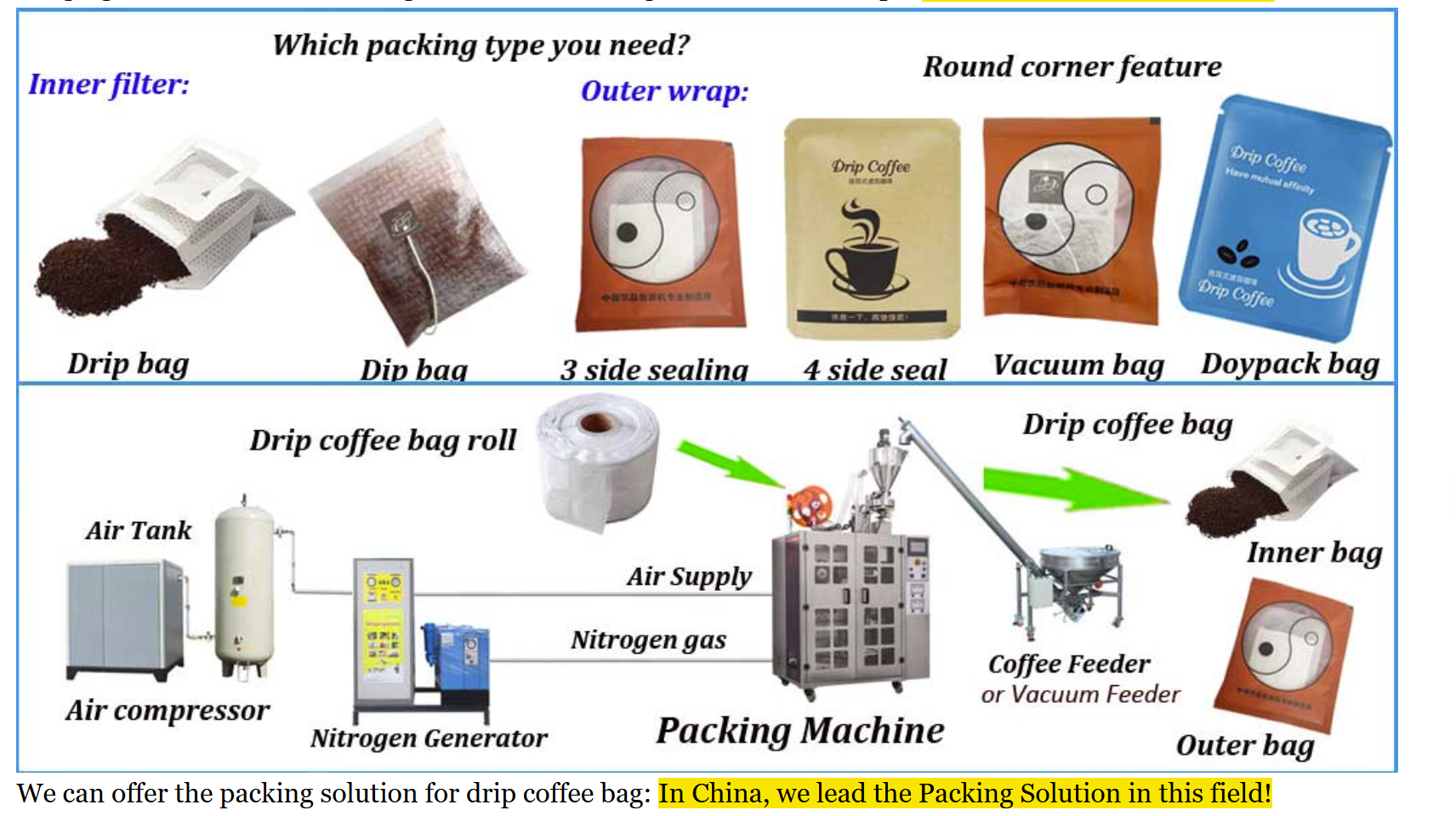

The C89K automatic drip coffee bag packing machine is a highly specialized packaging machinery designed for inner and outer bag packaging of drip coffee, tea leaves, herbal tea, health care tea, coffee, roots, and other small granule products, making it exceptionally versatile and efficient. This machine's core strength lies in its ability to *automatically complete both the inner filter bag (typically drip coffee filter paper, e.g., bag size: 9074mm) and the outer protective 4 side seal premade bag from its packing material in one integrated process, ensuring food safety and hygiene, space saving, and highly accurate produce weight filling (e.g., 5-15g accuracy +/-0.1g per bag).** With PID temperature controller for more accurate temperature adjustment and a PLC control system, human-machine interface, it delivers stable performance and convenient and fast adjustment, achieving a packing speed of 25-35 bags/min to produce fresh-keeping beautiful coffee pouches with an extended shelf life.

In my twelve years of manufacturing packaging machinery at XIAOSEN PACK, I have focused on solving real-world challenges for producers. The C89K automatic drip coffee bag packing machine is a prime example of this dedication. It is not just about bringing two bags together; it is about bringing them together flawlessly, ensuring both the freshness of the product and the fresh-keeping beautiful presentation that consumers expect. From my materials science engineering background, I understand the delicate nature of drip coffee filter paper and how critical precision is in forming and sealing it within an outer bag made of paper/plastic or plastic/aluminum/plastic. Our mission at XIAOSEN PACK is to deliver premium fresh food packaging machines that ensure efficiency, reliability, and compliance for every customer. The C89K embodies our commitment to offering cost-effective yet high-performance solutions for complex drip coffee bag packaging.

Why is the C89K Automatic Drip Coffee Bag Machine the Go-To for Inner and Outer Bag Packaging?

Many producers struggle with the logistical and quality control challenges of packaging drip coffee bags, often requiring separate machines or manual steps for the inner filter and outer protective envelope, leading to inefficiencies and inconsistencies. Why is the C89K automatic drip coffee bag packing machine specifically designed as the ideal go-to solution for seamless inner and outer bag packaging, and what unique advantages does its integrated operation offer for products like drip coffee, tea leaves, or herbal tea?

The C89K automatic drip coffee bag packing machine is the ideal go-to solution for seamless inner and outer bag packaging because it automatically completes both packaging stages for products like drip coffee, tea leaves, or herbal tea within one single machine, providing unparalleled integration and efficiency. This unique packaging machinery design avoids the complexities, labor, and potential errors of a two-machine setup, ensuring safe, hygienic, and space saving operation. The C89K's ability to precisely handle drip coffee filter paper for the inner bag (e.g., L:50-75mm, W:50-90mm with filter paper width 180mm creating bag size: 90*74mm) and then encase it in an outer bag size: L:120-130mm, W:100-110mm 4 side seal premade bag streamlines the entire drip coffee bag packaging process, maximizing production capacity and maintaining consistent freshness and a fresh-keeping beautiful appearance.

As someone deeply involved in packaging machinery design at XIAOSEN PACK, I can tell you that the C89K's strength lies in its singular, integrated approach to inner and outer bag packaging. When I started out, achieving this for delicate products like drip coffee bags or herbal tea often involved two separate machines and a lot of manual intervention. This led to errors, wasted packing material, and compromised freshness. The C89K fundamentally changes this. It handles the drip coffee filter paper for the inner bag, fills it with precise 5-15g accuracy +/-0.1g per bag of coffee, performs the inner seal, and then automatically picks up this filled inner bag and places it into a pre-formed 4 side seal premade bag for the outer protective layer. This entire sequence is orchestrated by a PLC control system, human-machine interface, making it very easy to operate and ensuring stable performance. This integration is not just about being space saving; it guarantees superior food safety and hygiene by minimizing human contact, reduces labor costs for cost efficiency, and significantly boosts production capacity by eliminating transfer steps. This creates a consistently fresh-keeping beautiful product, whether it is for drip coffee, tea leaves, or health care tea, destined for a long supply chain length in varied cold chain conditions.

Unique Advantages of the C89K's Integrated Inner and Outer Bag Packaging:

-

Seamless Automation:

- Mechanism: The machine independently manages the formation, filling, and sealing of the inner filter bag and then automatically inserts and seals it within the outer 4 side seal premade bag.

- Advantage: Eliminates manual handling between inner and outer bag processes, leading to exceptional efficiency, fewer errors, and reduced labor requirements, optimizing cost efficiency.

-

Enhanced Food Safety and Hygiene:

- Mechanism: All parts in direct contact with products are made to food sanitary standards, combined with automated processing minimizes human contamination.

- Advantage: Ensures a cleaner, more sterile packaging environment, critical for consumables like drip coffee, herbal tea, or health care tea during supply chain length and meeting consumer safety expectations.

-

Space Saving Design:

- Mechanism: A single machine unit (Dimension: L1700mm W900mm H2500mm) performs both internal and external packaging tasks.

- Advantage: Requires significantly less floor space than two separate machines, which is valuable for facilities with limited real estate, enhancing overall efficiency of plant layout.

-

Optimized Freshness & Shelf Life:

- Mechanism: The rapid, integrated process ensures minimal exposure of the coffee to ambient air before the final seal of the outer 4 side seal premade bag, which itself acts as a strong barrier protection. Nitrogen injection capabilities can often be integrated.

- Advantage: Maximizes product freshness and extends shelf life by quickly encapsulating the product in protective layers, preserving its flavor profile and fresh-keeping beautiful quality.

| Feature of C89K Integrated Packaging | Benefit for Production & Product Quality | Impact on Efficiency & Cost Efficiency |

|---|---|---|

| Automatic Inner & Outer Bag | Streamlined workflow, reduces human error, consistent product quality. | High efficiency, lower labor costs, optimized production capacity. |

| Food Sanitary Standards | Ensures food safety and hygiene for sensitive products like tea and coffee. | Protects brand reputation, reduces risk of contamination, enhances shelf life. |

| Space Saving Design | Compact footprint for complete inner and outer bag packaging solution. | Saves valuable factory floor space, potentially lowering operational overheads. |

| Consistent Quality | Precise handling of drip coffee filter paper and placement into outer bag. | Leads to fewer rejects, better fresh-keeping beautiful presentation, and cost efficiency. |

What are the Core Features and Specifications of the C89K Automatic Drip Coffee Bag Packing Machine?

A producer evaluating the C89K needs concrete details on its operational elements and capabilities to determine if it meets specific production demands for drip coffee bag packaging and other small granule products. What are the core features and specifications, including packing speed, filling range, and control systems, that define the C89K automatic drip coffee bag packing machine, ensuring its stable performance, precision, and ability to handle various packing material and packaging format and dimensions?

The core features and specifications of the C89K automatic drip coffee bag packing machine are designed for precision and reliability in inner and outer bag packaging. It boasts a packing speed of 25-35 bags/min with a filling range: 5-15g accuracy +/-0.1g per bag for excellent produce weight consistency. Its inner bag handles drip coffee filter paper for sizes like L:50-75mm, W:50-90mm (filter paper width 180mm creating bag size: 9074mm), while the outer bag is a 4 side seal premade bag with dimensions of L:120-130mm, W:100-110mm, compatible with packing material such as paper/plastic, plastic/aluminum/plastic, and kraft paper. The machine ensures stable performance with its PID temperature controller for more accurate temperature adjustment and PLC control system, human-machine interface for convenient and fast adjustment. Built for food safety and hygiene, all parts in direct contacts with products are made to food sanitary standards. It operates on single phase, 220V, 50HZ, 5.5KW, weighing 800kg with dimension: L1700mmW900mm*H2500mm, making it a robust and adaptable solution for products like tea leaves, herbal tea, and roots.

Dive deeper Paragraph:

As an engineer with XIAOSEN PACK, I designed machines for stable, precise operation, and the C89K is no exception. Its specifications are not just numbers; they represent consistent quality and output. The packing speed of 25-35 bags/min is excellent for precision drip coffee bag packaging, where each inner bag filled with 5-15g accuracy +/-0.1g per bag of tea leaves or coffee needs careful handling before being wrapped in the outer bag. The PID temperature controller is crucial for perfect packaging piece seal flat, clear embossing across various packing material types like paper/plastic or plastic/aluminum/plastic. A precise temperature ensures strong seals without burning delicate drip coffee filter paper for the inner bag (bag size: 90*74mm). The PLC control system, human-machine interface makes it very easy to operate for any packaging format and dimensions change within its stated range, ensuring convenient and fast adjustment. We have imported some cylinder parts to guarantee accuracy and stability of performance. My emphasis on food safety and hygiene means all parts in direct contacts with products are made to food sanitary standards, extending its versatility beyond coffee to health care tea and roots. These features ensure fresh-keeping beautiful products with extended shelf life, even in demanding cold chain conditions and long supply chain length environments.

Detailed Features and Specifications of the C89K:

| Feature Category | Specific Feature / Parameter | Description & Impact |

|---|---|---|

| Product Suitability | Inner and outer bag packaging for tea leaves, herbal tea, health care tea, coffee, roots, and other small granule products. | Versatility: Designed for a wide range of granular products, highlighting its precision for delicate items like drip coffee and specialized teas. This broad application extends its cost efficiency. |

| Automation & Integration | The inner bag and outer bag of this machine are automatically completed by one same machine. | Efficiency & Safety: Centralized operation reduces labor, minimizes contamination, is safe, hygienic and space saving. Crucial for high production capacity and consistent quality. |

| Control System | PID temperature controller for more accurate temperature adjustment. | Precision: Ensures exact and consistent sealing temperatures, vital for perfect packaging piece seal flat, clear embossing with diverse packing material (e.g., drip coffee filter paper, plastic/aluminum/plastic) and maintaining freshness. |

| PLC CONTROL SYSTEM, HUMAN-MACHINE INTERFACE, IT IS VERY EASY TO OPERATE. | User-friendliness: Allows for intuitive operation, monitoring, and convenient and fast adjustment for changing product specifications, reducing operator training time and errors, ensuring stable performance. | |

| Hygiene | All parts in direct contacts with products are made to food sanitary standards. | Food Safety and Hygiene: Guarantees that the packaged product remains uncontaminated, essential for all food and health-related items, and critical for long shelf life and trust in the flavor profile. |

| Components | Some parts of the cylinder are imported, ensuring the accuracy and stability of performance. | Reliability: Utilization of high-quality imported components enhances the machine's overall stable performance and longevity, minimizing downtime and maintenance needs for long-term cost efficiency. |

| Packing Material | Paper/plastic, plastic/aluminum/plastic, drip coffee filter paper, kraft paper. | Flexibility: Compatible with common high-barrier and decorative packaging materials, allowing producers to choose based on freshness requirements, packaging aesthetics, and cost efficiency. |

| Bag Type | 4 side seal premade bag for outer bag; inner filter bag. | Robustness & Aesthetics: The outer 4 side seal offers superior barrier protection and a premium, uniformly sealed appearance, contributing to fresh-keeping beautiful product presentation and enhancing shelf life, especially for cold chain conditions. |

| Outer Bag Size | L: 120-130mm, W: 100-110mm. | Standardization: Caters to common retail packaging format and dimensions for single-serve drip coffee bags or tea bags. Provides a clear target for packaging materials procurement. |

| Inner Bag Size | L: 50-75mm, W: 50-90mm (filter paper width 180mm, bag size: 90*74mm). | Precision Specifics: Defines the size parameters for the delicate inner filter bag, critical for precise filling and proper brewing. The bag size: 90*74mm is a popular standard. |

| Packing Speed | 25-35 bags/min. | Production Capacity: Provides a clear indication of throughput for this specific inner and outer bag packaging machine, allowing producers to calculate their daily output and efficiency. |

| Filling Range & Accuracy | 5-15g accuracy +/-0.1g per bag. | Consistency & Cost Efficiency: High accuracy ensures consistent flavor profile for the consumer and reduces product giveaway, directly improving cost efficiency. |

| Power | Single phase, 220V, 50HZ, 5.5KW. | Utility Requirement: Standard industrial power specification, indicating energy consumption and electrical setup needs. |

| Weight & Dimension | Weight 800kg, Dimension: L1700mmW900mmH2500mm. | Footprint & Installation: Provides crucial information for facility planning, transport logistics, and placement, confirming its space saving characteristic compared to multiple machines. |

Conclusion

The C89K automatic drip coffee bag packing machine is a powerful, integrated solution for precise inner and outer bag packaging of drip coffee and various teas. Its automated process, stable performance, and capacity for convenient and fast adjustment ensure optimal freshness and cost efficiency, producing fresh-keeping beautiful pouches from its packing material with consistent accuracy.