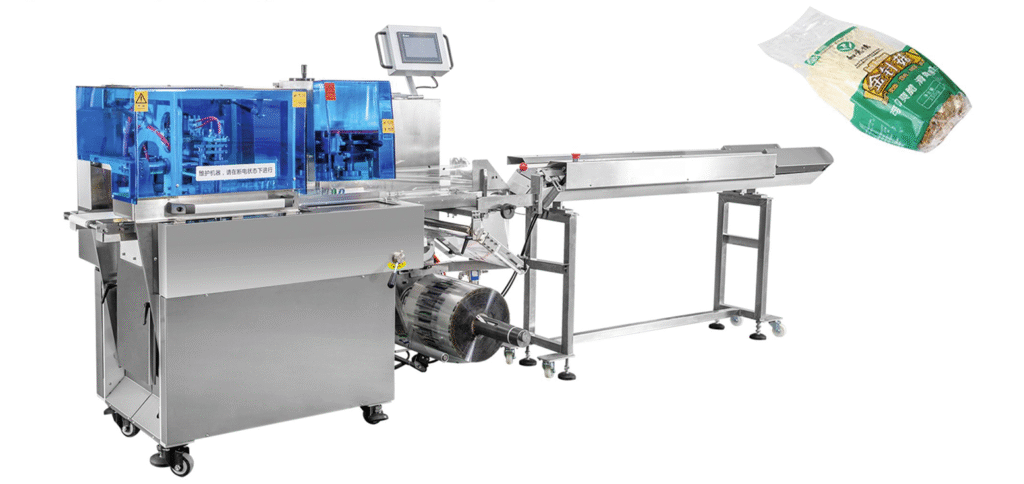

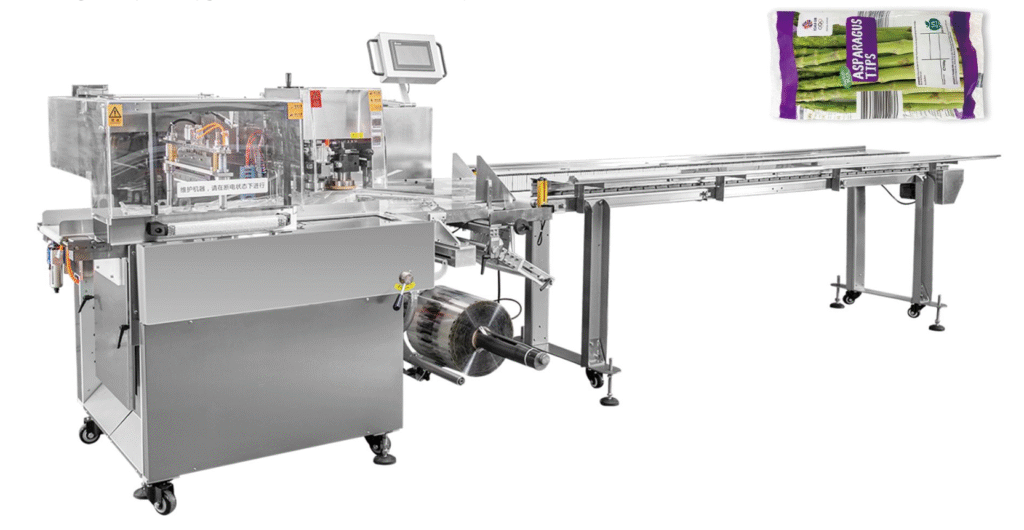

The XSCR-400X is a high-performance flow wrapping machine designed for fresh produce, fruits, vegetables, and edible fungi. Built with advanced control systems and precision components, it ensures efficient, hygienic, and reliable packaging to extend shelf life and maintain freshness.

Key Features

Wide Application – Suitable for packaging vegetables, mushrooms, fruits, and other fresh food items.

High Speed & Efficiency – Packaging speed of 10–60 bags per minute with smooth and stable operation.

Flexible Film Options – Works with composite film, aluminum-coated film, printed film, BOPP, CPP, and other food-grade materials.

Compact & Durable Design – Space-saving structure with strong build quality for long-term use.

Smart Control System – Equipped with DELTA PLC & servo motor, OMRON temperature controller, and KEYENCE sensor for precision and easy operation.

Hygienic Packaging – Seals products tightly, protecting freshness while keeping packaging clean and professional.

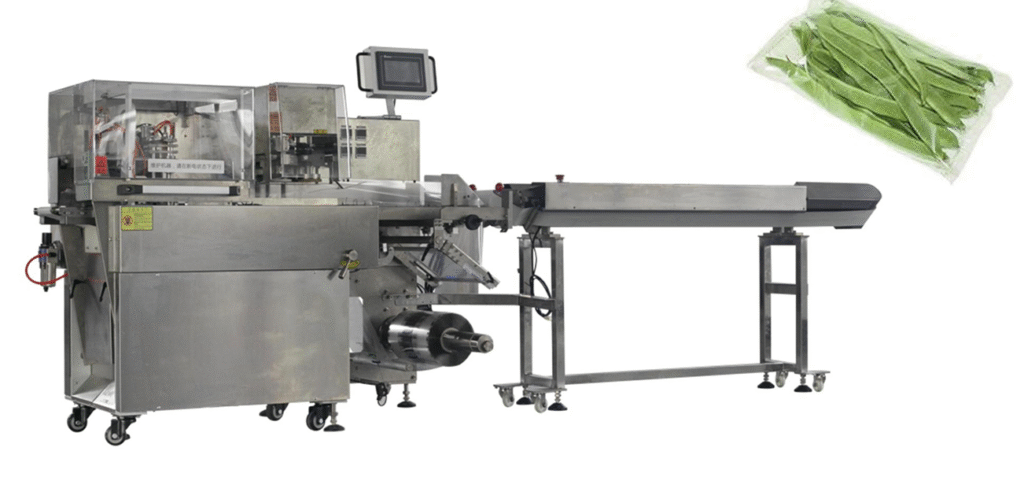

The XSCR-400AX is a fully automatic flow wrapping machine specially designed for fresh mushrooms, vegetables, fruits, and other delicate produce. With advanced automation, precision control, and durable construction, it delivers fast, hygienic, and reliable packaging that keeps food fresh and visually appealing.

Key Features

Versatile Applications – Perfect for packaging mushrooms, fruits, vegetables, and similar fresh produce.

High Efficiency – Achieves a packaging speed of 10–60 bags per minute with smooth and stable performance.

Flexible Film Compatibility – Supports multiple materials including composite film, aluminum-coated film, printed film, BOPP, CPP, and other food-grade packaging.

Durable & Compact Design – Built with a strong frame and space-saving layout for long-term industrial use.

Advanced Control System – Equipped with DELTA PLC & servo motor, OMRON temperature controller, and KEYENCE electronic eye for precision and easy operation.

Safe & Hygienic Packaging – Ensures tight sealing, clean edges, and extended shelf life with a professional appearance.

XSCR-650X Fresh produce Packaging Machine

Key Specifications

- Packaging Speed: 10–60 bags/min

- Film Transport Speed: 20 m/min

- Maximum Film Width: 620 mm

- Maximum Film Diameter: 300 mm

- Packaging Product Size:

- Width: up to 260 mm

- Height: up to 120 mm

- Cut-off Range (Length): >90 mm (can be sealed and cut)

Electrical & Mechanical

- Electrical Capacity: 220V / 5 KVA

- Weight: 650 kg

- Dimensions: L4833 × W1235 × H1500 mm

Core Components

- PLC: DELTA

- Servo Motor: DELTA

- Temperature Controller: OMRON

- Electronic Eye: KEYENCE

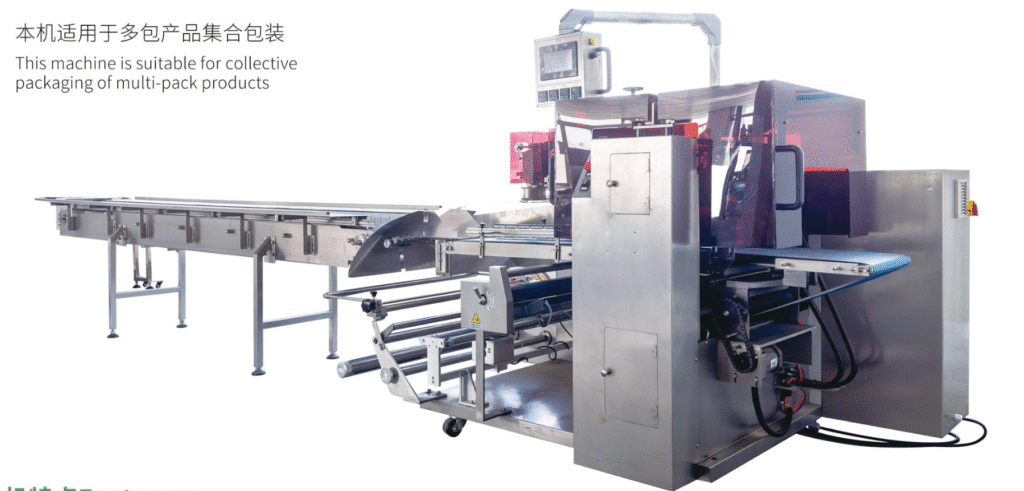

XSCR-1080X Automatic Flow Packaging Machine

Key Features

- Three servo drives with functions: empty package detection, automatic replenishment, etc.

- Human-machine interface, PLC control

- Photoelectric detection and automatic tracking

- Automatic centering of hanging paper roller

- Multiple safety protection measures

- Touch screen with 360° rotation

- Adjustable bag maker

- Pneumatic corner folding

- Alarm shutdown system

- Anti-cut function

- Manual knife adjustment

- Product memory (10 groups)

- Reciprocating horizontal sealing structure

Technical Specifications

- Model: XSCR-1080X

- Max Film Size: 1020 mm

- Speed: 10–50 bags/min

- Bag Length: 200–600 mm

- Product Width: 70–350 mm

- Bag Making Width: 5–150 mm

- Product Height: 50–120 mm

- Power: 4.5 kW

- Weight: 1600 kg

- Dimensions: L6300 × W1600 × H1900 mm

- Air Capacity: 0.5 Mpa, 80 L/Action

- Power Supply: 220 V / 50 Hz

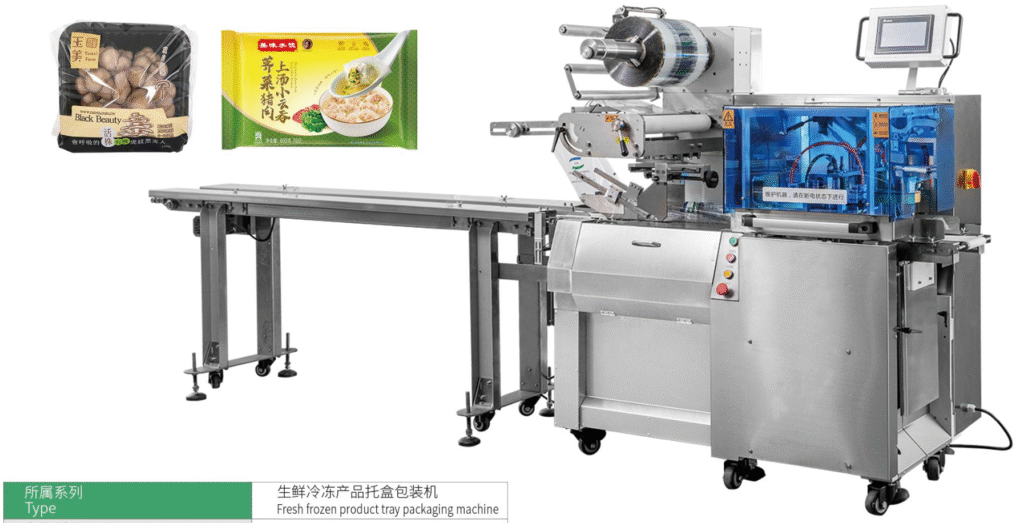

XSCR-500S Fresh Vegetable Packaging Machine

The XSCR-500S is a high-performance packaging machine designed for fresh and frozen food trays. It delivers fast, reliable, and hygienic packaging with advanced automation control.

Key Features

- High Efficiency: Speed of 10–60 bags/min with film transport up to 20 m/min.

- Flexible Packaging: Handles film widths up to 500 mm, film diameters up to 300 mm, and product sizes up to 160 mm (W) × 120 mm (H).

- Accurate Cutting: Supports cut-off lengths of 90 mm and above.

- Durable Build: Heavy-duty structure weighing 620 kg, with machine dimensions L3580 × W975 × H1600 mm.

Technical Specifications

- Electrical Capacity: 220V / 5KVA

- PLC System: DELTA

- Servo Motor: DELTA

- Temperature Controller: OMRON

- Electronic Eye: KEYENCE

Advantages

- Consistent and precise sealing & cutting

- Built with internationally recognized brands for reliability

- Suitable for fresh produce, frozen foods, and tray-packed products

The XSCR-600B is a fully automatic packaging solution designed for fresh produce, vegetables, and frozen foods. With its high efficiency, stable performance, and advanced control system, it ensures reliable sealing and cutting for extended product freshness.

Key Specifications

- Packaging Speed: 10–60 bags/min

- Film Transport Speed: Up to 20 m/min

- Maximum Film Width: 620 mm

- Maximum Film Diameter: 300 mm

- Packaging Product Size:

- Width: Up to 260 mm

- Height: Up to 120 mm

- Cut-off Range (Length): ≥ 90 mm (sealable and cuttable)

Technical Details

- Electrical Capacity: 220V / 5 KVA

- Machine Weight: 620 kg

- Machine Dimension: L4833 × W1235 × H1500 mm

Core Components

- PLC Controller: DELTA

- Servo Motor: DELTA

- Temperature Controller: OMRON

- Electronic Eye: KEYENCE

XSCR-900WBS Key Features

- Automatic Operation – No empty package function; the machine stops automatically when material runs out, with film cutting also halted. Materials are pushed and replenished automatically, reducing manual work.

- High Efficiency – Dual servo single inverter control allows bag length adjustment without changing unloading setup, saving time and film.

- Reliable Sealing – Reciprocating end sealing mechanism and gusseting device ensure stronger, more precise seals and enhanced package appearance.

- Intelligent Control – High-sensitivity photoelectric tracking system ensures accurate sealing and cutting positions. Independent PID temperature control adapts to various packaging materials.

- Ease of Use & Maintenance – Simple transmission system for reliability and durability; fault self-diagnosis for quick troubleshooting. All controls are software-based, allowing easy upgrades and adjustments.

Technical Specifications

- Film Width: Max. 900mm

- Bag Length: 250mm–∞ (customizable)

- Bag Width: 180–400mm

- Product Height: 50–120mm

- Roll Diameter: Max. 320mm

- Packaging Speed: 20–30 bags/min

- Power Supply: 220V, 50/60Hz, 4.5kW

- Machine Size: L4185 × W1340 × H1508 mm

- Weight: 1200kg

Applications

Designed for packaging a wide variety of fresh and frozen products, including:

- Vegetables

- Fruits

- Meat and poultry portions

- Dumplings and buns

- Other fresh food items

The XSCR-650S is a high-performance tray packaging machine designed for fresh and frozen food products.

Key Specifications

- Packaging Speed: 10–60 bags/min

- Film Transport Speed: Up to 20 m/min

- Maximum Film Width: 620 mm

- Maximum Film Diameter: 300 mm

- Packaging Product Size:

- Width: Up to 260 mm

- Height: Up to 120 mm

- Cut-off Range (Length): ≥ 90 mm (sealable and cuttable)

Technical Details

- Electrical Capacity: 220V / 5 KVA

- Machine Weight: 580 kg

- Machine Dimension: L4833 × W1235 × H1500 mm

Core Components

- PLC Controller: DELTA

- Servo Motor: DELTA

- Temperature Controller: OMRON

- Electronic Eye: KEYENCE

Industries and Products that Benefit Most from Horizontal Flow Wrapping:

Baked Goods & Confectionery:

- Products: Cookies, biscuits, cakes, bread rolls, pastries, chocolate bars, candy.

- Benefits: Gentle handling for delicate items, high speed for high-volume production, protection against moisture and air to maintain freshness and texture. Achieves aesthetic appeal for retail.

Snack Foods:

- Products: Snack bars (granola bars, protein bars), crackers, small bags of chips.

- Benefits: Extremely high output for mass production, consistent sealing for freshness, cost-effective packaging for single servings.

Fresh Produce:

- Products: Individual fruits (apples, pears, oranges), tomatoes, bell peppers, fresh herbs, small trays of mushrooms or berries.

- Benefits: Protects delicate items from bruising and contamination, extends shelf life through hermetic sealing, allows for Modified Atmosphere Packaging (MAP) options, crucial for various “cold chain conditions.”

Frozen Foods:

- Products: Individual frozen items (e.g., fish fillets, chicken pieces, prepared meals in trays, frozen vegetables).

- Benefits: Creates strong, barrier-resistant seals that prevent freezer burn, maintains product quality over extended “supply chain length,” and protects against moisture loss during freezing and thawing.

Meat & Dairy (Single Items/Small Portions):

- Products: Individual cuts of meat (e.g., pork chops, steak portions), sausages, cheese slices.

- Benefits: Hygienic packaging, extends shelf life, protects against bacterial contamination, suitable for MAP applications for enhanced freshness and color.

Non-Food Industries:

- Products: Medical devices (syringes, bandages), cosmetics (soap bars, small bottles), hardware (screws, small parts), stationery, promotional items.

- Benefits: Ensures sterility or cleanliness, provides protection against dust and damage, offers attractive and controlled presentation for retail or multi-packs.

| Industry/Product Category | Typical “Produce Type” & “Weight” | Key Flow Wrap Advantage for this Category |

|---|---|---|

| Bakeries & Confectionery | Croissants, cookies, snack cakes (10g-500g) | Gentle handling, high speed, freshness, attractive presentation |

| Snack Foods | Granola bars, small chip bags (20g-150g) | Extreme speed, cost-efficiency, consistent portion control |

| Fresh Produce (Tray/Loose) | Tomatoes, mushrooms, berries (50g-1kg) | Product protection, extended freshness, hygiene (MAP compatible) |

| Frozen Foods | Fish fillets, prepared meals, vegetables (100g-1kg) | Prevents freezer burn, maintains quality over long storage |

| Non-Food Items | Small hardware, medical devices, cosmetics (5g-500g) | Protection from environment, sterility, neat presentation |